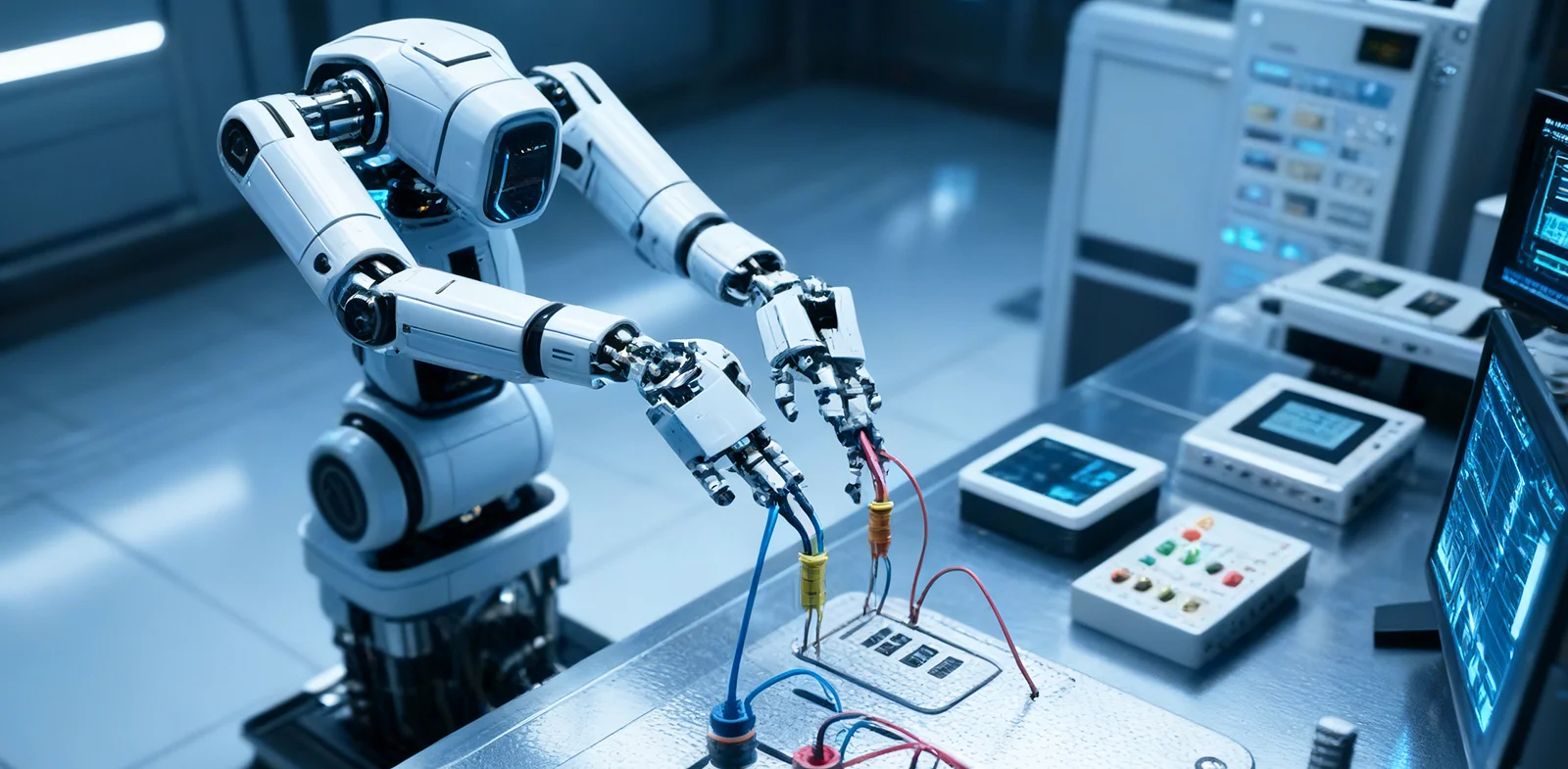

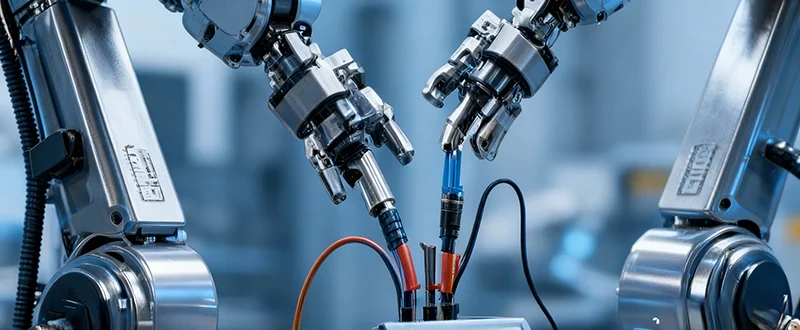

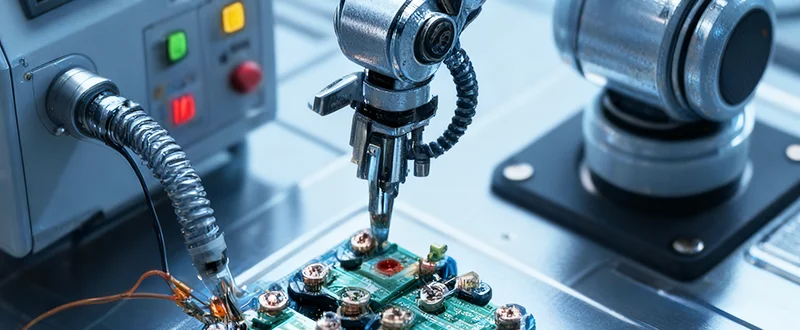

Robots, as complex systems integrating mechanics, electronics, sensing, and artificial intelligence, fundamentally depend on the quality of their electrical performance for their overall capability and reliability. Electrical performance testing runs through the entire cycle of robot R&D, production, and acceptance. It is far more than a simple power-on check; it is an in-depth verification and efficiency evaluation of its "life system"—the power architecture, powertrain, signal integrity, and energy management.

Electrical performance testing is not only the cornerstone for ensuring the safe and stable operation of robots and preventing electrical risks, but also a key means to accurately quantify their working endurance, dynamic response, and energy efficiency levels, thereby ensuring design goals are met. In the era where robots are moving towards large-scale, industrial applications, establishing and implementing a strict electrical performance testing system is an inevitable requirement to enhance product competitiveness, win market trust, and promote the sustainable and healthy development of the industry.